(1) Expansion coefficient

It can be known from the calculation formula of heat resistance of glass: heat resistance is inversely proportional to the coefficient of expansion. Therefore, the lower the expansion coefficient, the better the heat resistance. The expansion coefficient of quartz glass is only 1/10~1/20 of that of ordinary industrial glass, so its heat resistance is the best. Transparent quartz glass thin-walled products can be heated to 1000°C and quenched in water without breaking; when heated to 1300°C, they can withstand air quenching.

In the glass composition, all oxides that can reduce the expansion coefficient (such as SiO2, B2O3, TiO2, ZrO2, etc.) can improve heat resistance.

The expansion coefficient of eucryptite and titanate materials is negative, and electronic products often use this feature to mix eucryptite powder or titanate material into low-melting solder glass to reduce the expansion coefficient of the solder.

(2) The shape and thickness of the product

The essence of glass heat resistance is that the temperature difference between the outer surface and the interior of the glass is formed due to the thickness of the product when the product undergoes a rapid temperature change. If the temperature difference causes the internal stress to exceed the tensile strength of the glass, the product will burst. Therefore, the greater the thickness of the product, the greater the internal stress caused by the rapid temperature change, and the temperature difference that can be tolerated will inevitably decrease.

In addition, if the shape of the product has sharp corners, it will also reduce its heat resistance due to stress concentration.

(3) Abrupt change in temperature

When the glass product is heated, the temperature of the outer surface is higher than the temperature of the interior, so the product is subjected to compressive stress; on the contrary, when the product is cooled, the temperature of the outer surface is lower than that of the interior, so the product is subjected to tensile stress. As we all know: the compressive strength of glass is much higher than the tensile strength, so the temperature difference that glass can withstand when heated is higher than that when it is cooled.

(4) Medium and its characteristics

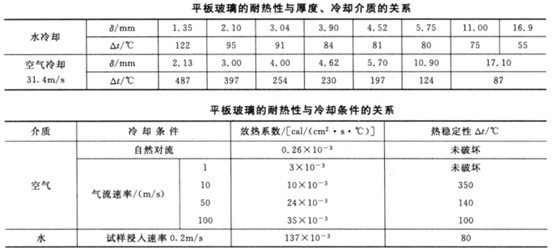

Different media, the heat resistance of glass is also very different. The following table lists the heat resistance of different thicknesses of flat glass in water cooling and air cooling. It can be seen that the heat resistance of glass in air cooling is higher than that in water cooling. As far as air media is concerned, the faster the air flow rate and the relatively high cooling intensity, the lower the heat resistance of the glass.

(5) Chemical composition

In addition to improving the heat resistance of the glass composition by reducing the coefficient of expansion, the composition containing Al2O3, ZnO, Li2O can also increase its heat resistance.

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : No.2 plant of Baolong factory area, Anbo Science Park, Baolong street, Longgang District, Shenzhen, Guangdong Province, China