Many components of the vacuum resistance furnace can be made of graphite, of which heating elements and reflective screens are the most widely used.

In the past, heating elements of vacuum resistance furnaces were mostly made of tungsten, molybdenum, tantalum and other metals. In recent years, graphite heating elements have become more and more widely used, especially due to the appearance of graphite cloth, which has promoted the application of graphite heating elements.

The heating element of the vacuum resistance furnace made of graphite has a series of advantages: 1) Graphite has excellent performance to meet the various requirements of the heating element of the vacuum resistance furnace. 2) It is easy to process and can meet the requirements of various vacuum resistance furnace heating elements. 3) Simple structure, convenient installation and disassembly. Graphite heating elements are much more convenient than metal heating elements. 4) The price is cheap and the cost is low.

Graphite cloth is an excellent material for heating elements in vacuum resistance furnaces, because: 1) Graphite cloth has low thermal inertia, so it heats up quickly and cools down quickly, which is ideal for heating elements. 2) It is extremely flexible, does not melt at high temperatures, is deformable, and has strong thermal shock resistance. 3) The radiation efficiency is high (up to 90%), and the radiation area is large, pretending that the heating element has high thermal efficiency and saves energy. 4) Easy to process, just cut with scissors. 5) Easy to degas and good vacuum performance.

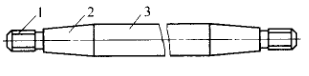

The graphite heating element can be made into a rod shape, a tube shape, a plate shape, or a cloth shape as required. The graphite rod heating element can be used in any vacuum resistance furnace of different sizes. In order to prevent stress damage due to thermal expansion and contraction, it is generally made into the structure shown in the figure below.

Graphite rod heating element (1 threaded joint; 2 transition section; 3 heating section)

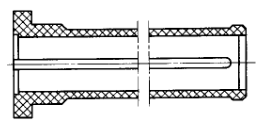

The tubular heating element is used in the vertical vacuum resistance furnace. It is characterized by small temperature difference between the heating element and the heated part, uniform heating, and small furnace heat loss. When the length of the graphite heating element is insufficient and the thickness cannot be reduced due to the strength conditions In order to increase the resistance of the graphite heating element, threaded grooves or longitudinal and lateral grooves are usually cut on the sidewall.

Graphite tube heating element

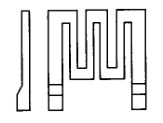

Graphite plate heating element

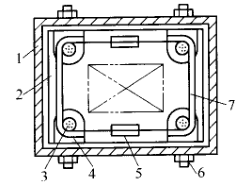

The structure of the graphite cloth heating element is also very simple. As shown in the figure, the graphite felt 2 is wound into three components through the graphite support 4 and the alumina insulating rod 3, and each component is fixed on the stainless steel frame with a graphite splint 5 and a graphite nut 6 On 1, the electrode introduction is also connected through the graphite splint, which can be connected into a triangle or star according to the needs.

Graphite cloth heating element

(1 stainless steel frame; 2 graphite felt; 3 alumina insulating rod; 4 graphite support; 5 graphite splint; 6 graphite nut; 7 graphite cloth heating element)

(Huiputech)

Download Latest Catalog

2026-01-28

Z-S-CF40-1216S,Z-S-CF40-1216M,Z-S-CF40-1216L

2026-01-28

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.