In vacuum system assembly, flexible vacuum pipe joints are used to adapt to thermal expansion or position adjustment (relative movement between parts is required), or to isolate vibration and weak parts from stress damage.

For the front low vacuum of the ultra-high vacuum system, flexible pipelines such as vacuum rubber tubes and plastic tubes can be used. The wall thickness of the pipeline must be able to withstand atmospheric pressure, and the thin-walled tube must be equipped with reinforcements (such as wire springs) in the tube. This kind of hose is often used in the front-stage roughing system to isolate the vibration of the mechanical vacuum pump.

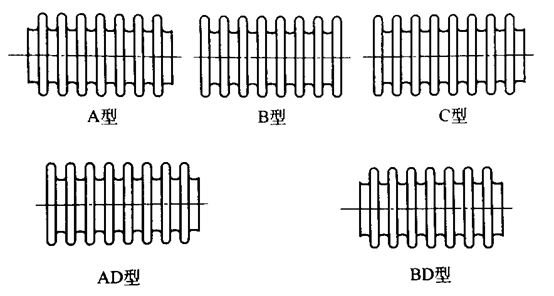

The movable parts of the ultra-high vacuum system, such as the moving mechanism of the valve, usually use metal bellows made of copper, stainless steel, nickel-chromium-iron alloy and other materials. A typical rolled or hydroformed metal bellows is shown in the figure.

Type A, Type B, and Type C are bellows with open ends; Type AD and BD are bellows with one end closed and one end open. For this type of metal bellows, the nodes per unit length and the displacement of each node are small, and the length of each bellows is also limited by the processing equipment.

Another type of bellows is a welded bellows. The nodes of the welded bellows per unit length and the displacement of each node are relatively large, but the cost is high, the inner wall is not easy to clean, and it can only be cleaned by baking.

The wall of the metal corrugated pipe is very thin, and the welding part of the thick flange needs to be processed into the same thin wall as the corrugated pipe, otherwise it is easy to weld through the thin-walled corrugated pipe. The welding seam should be located inside the vacuum as much as possible to avoid the formation of "dead space" that is not conducive to vacuuming. In order to increase the strength of the weld, the outer side can be positioned and reinforced by intermittent welding.

When the bellows is used in the vacuum pipeline, the atmospheric pressure can shorten the bellows. This requires that the two ends of the connecting system have sufficient mechanical support strength or be fixed with support rods to limit the expansion and contraction of the atmospheric pressure compression bellows.

The bellows is the most easily damaged component in the vacuum system. Be careful not to let it bear excessive stress, otherwise it will affect its service life. Corrugated pipes should not be cleaned with strong corrosive agents, and they are easily scratched, so they should be protected.

(Huiputech)

Download Latest Catalog

2026-01-28

Z-S-CF40-1216S,Z-S-CF40-1216M,Z-S-CF40-1216L

2026-01-28

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.