Metal-sealed ultra-high vacuum flanges For ultra-high vacuum systems that need to be frequently placed in the atmosphere to replace workpieces, each time the container flange is re-disassembled and assembled, it is difficult to ensure a reliable seal due to the indentation of the knife edge or the knife edge being damaged. Use disposable sealed metal gaskets. Every time you open the container, you need to replace a new flange sealing ring. Flanges sealed with aluminum foil are often difficult to adhere to the stainless steel flange surface due to diffusion welding during high-temperature baking. Removal will bring troubles to the replacement of the sealing ring. For ultra-high vacuum systems with an ultimate pressure of not higher than 10-6~10-7Pa, fluorine rubber can be used for sealing, and corresponding measures should be taken to reduce the disadvantage that the rubber outgassing rate is larger than that of metal.

Fluorine rubber can withstand high-temperature baking at 250~300℃, and can work at 125℃ for a long time under pressure. It has a lower outgassing rate than the commonly used nitrile rubber. The performance parameters of domestic F26 fluororubber are shown in the table.

Density g·cm-3 | 1.82 |

Elongation % | 150~250 |

Embrittlement temperature ℃ | -35~-45 |

Tensile strength MPa | 10.0~15.0 |

Hardness (HS) | 70±5 |

Working temperature ℃ | 250(200h)~20 |

Outgassing rate (room temperature) Pa·L·s-1·cm-1 | 1~3×10-5 |

Note: Under 250℃, 200h, then return to room temperature, tensile coefficient 0.8, elongation coefficient 0.8.

Try to use an O-shaped rubber ring with a smaller cross-sectional diameter. When designing the seal groove, use a structural design that allows the two flanges to be pressed together to minimize the rubber area exposed to the vacuum side.

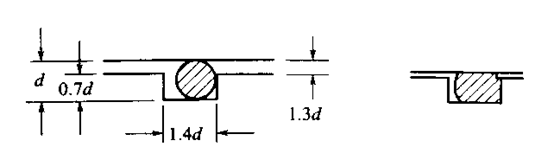

The commonly used O-ring seal groove size is shown in the figure. The compression of the rubber ring is 30% of the cross-sectional diameter of the O-ring, and the groove width is at least 1.4 times the cross-sectional diameter of the O-ring. The inner diameter of the O-ring should be slightly smaller than The inner diameter of the sealing groove can make the rubber ring close to the sealing groove after assembly. The O-ring has enough lateral deformation space outward, and the two flange planes are pressed together to press all the O-rings into the sealing groove without being squeezed out of the groove. In order to facilitate processing, the bottom surface angle of the sealing groove can be processed to a radius equal to 1/5 of the cross-sectional diameter of the O-ring. The roughness of the sealing surface must be at least 1.6μm (preferably 0.8μm). The outer edge of the groove is chamfered by 0.13mm and needs to be trimmed and clean to avoid scratching the O-ring during assembly.

Reducing the temperature of the rubber sealing ring or adopting a double-channel sealing ring with intermediate air extraction can effectively reduce the air outflow rate and air leakage rate of the rubber.

(Huiputech)

Download Latest Catalog

2026-01-28

Z-S-CF40-1216S,Z-S-CF40-1216M,Z-S-CF40-1216L

2026-01-28

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.