Vacuum connectors, also called vacuum electrodes, are used for power supply or signal transmission in a vacuum chamber, and are an indispensable basic device for vacuum equipment or vacuum instruments. However, some people found a vacuum connector on the Internet and found that the vacuum connector is normal and stable in normal use. Why did it suddenly discharge and fire? When you disassemble the vacuum connector plug, you will find that the pins are on the pins. There are traces of burning black. Is there a problem with the quality of the vacuum connector? If there is a quality problem, why hasn't it been used for so long before? In fact, when this happens, there are still rules to follow.

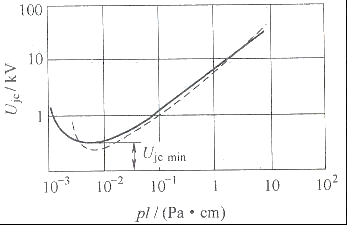

Under normal circumstances, the technical parameters of the vacuum connector will indicate the withstand voltage value, the vacuum degree and the temperature range used, and these technical parameters are higher than the actual requirements when selecting the type, so why does discharge sparking occur? The discharge in a vacuum is not as we understand it. It is believed that the insulation will be improved after the vacuum is drawn, and it will be more difficult to ignite. In fact, in a specific vacuum range (usually an absolute vacuum of 150Pa~10Pa), when the electrode voltage reaches a certain critical value (this critical value of breakdown voltage is related to the electrode material and shape, electrode spacing, and gas composition and content in the vacuum). Related, generally 100V~550V), it is easy to discharge. We can find that this vacuum range belongs to the rough vacuum, which is far from the working limit indicated by the vacuum connector. When the vacuum continues to increase to medium vacuum or high vacuum, the discharge phenomenon will disappear again. That is to say, only in a certain vacuum degree range, a certain voltage range, discharge sparking is easy to occur, and this range is very easy to reach. The vacuum connector used is not always safe to use within the scope of technical parameters. It will have a very narrow unsafe range, and connector manufacturers and suppliers are not aware of this. a little. This also explains why the vacuum connector suddenly ignited, and it was used well before.

The cause of the problem is not that the vacuum connector has quality problems. The vacuum connector being used can indeed work stably within the range of its marked technical parameters. The root cause is actually that a connector that is not suitable is selected when the vacuum connector is selected. If the vacuum connector used may work in the range of absolute vacuum of 150Pa~10Pa and working voltage of 100V~550V, please note that even if this range is not its normal working range, as long as the connector is occasionally in this range when energized , Then we should focus on its anti-sparking design. Sparking is actually voltage breakdown, which means that the insulation level is not enough. This insulation level is not as high as the technical parameters indicate, and it is fixed. If there is no special anti-sparking design, the insulation level is very fragile and changing. When a spark occurs, the insulation level is the most vulnerable.

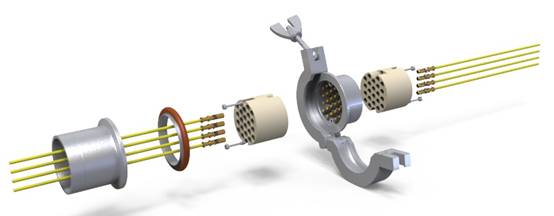

After a long period of research and practical testing, Huipu Technology has summarized a set of mature anti-sparking design experience and applied it to every vacuum connector product. In short, it is necessary to maintain the convenience of plugging and unplugging on both sides, but also to prevent the hidden danger of ignition caused by the inherent gap of plugging and unplugging. Each conductive component in the vacuum connector must always be insulated from each other, and the conductive component must not be exposed to the discharge range of other non-equal-potential conductive components. How exactly did it do it? What is the difference between Huipu Technology's vacuum connector and the common vacuum connectors on the market?

As a supplier of vacuum connectors focusing on small current, low voltage, and high-density pin count, the first thing to ensure is the quick and convenient assembly and use of users. It is different from the high-voltage vacuum electrode, it has ample space for wiring and insulation operation. The denser the pins means the smaller the operation space and the more difficult the assembly. If the high-density pins are connected by welding + heat-shrinkable tube, there will be two hidden dangers in case of improper operation: it is inconvenient to repair the false soldering, and the heat-shrinkable tube is not properly covered. In particular, if the heat shrinkable tube is not properly sheathed, it will cause the insulation between the pins to be reduced under certain working conditions. Huipu Technology adopts the design of inserting the plug after the wire is crimped. Because the pin sinks deep enough after inserting, there is no need to insulate each pin separately; in addition, each pin can be withdrawn separately without any order , So the problem of inconvenience in repair is solved.

After the plug is inserted into the vacuum connector, fasten it with screws to prevent it from loosening. There is a scale indication when inserting to ensure that the insert is in place.

The insulation retention after the plug and the connector are matched is the patent of the anti-fire structure of Huipu Technology. Safety and stability can also be ensured when the above-mentioned ignitable working conditions occur.

In addition, the plug design of Huipu Technology is small and compact, which will greatly reduce the space occupied by the vacuum chamber; when multiple plugs are densely arranged, it is easy to plug and unplug.

(Huiputech)

Download Latest Catalog

2026-01-28

Z-S-CF40-1216S,Z-S-CF40-1216M,Z-S-CF40-1216L

2026-01-28

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.