The welding performance of Kovar alloy is very good, and after welding after nickel plating, good air tightness can still be obtained. Kovar alloy parts should be subjected to stress relief annealing before welding to prevent thermal cracks caused by stress. Due to the large thermal resistance (small thermal conductivity) of Kovar alloy, the heat conduction is very slow. When argon arc welding of cermet, metallic glass sealing parts and Kovar alloy parts, the welding seam should be away from the sealing of ceramic or glass The surface is 5~6mm to prevent the ceramic or glass from bursting. There should be no silver and its alloys near the weld to avoid cracking of Kovar alloy.

(Huiputech)

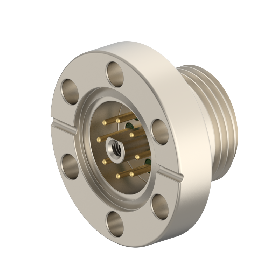

Z-S-CF16-0810S,Z-S-CF16-0810M,Z-S-CF16-0810L

2025-11-04

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.