After the metal parts and the connected glass parts are made according to the requirements on the drawings, they must first be cleaned and dried. The surface of the joint must be ground and polished. When the accuracy is reached, perform the necessary cleaning, even ultrasonic cleaning.

For the surface treatment of metals, in addition to achieving accuracy on the surface, degassing treatment (such as N2, H2 absorbed during smelting, etc.) or H2 removal is also required. Its purpose is to prevent the defect of re-forming bubbles during the joining and heating process.

In addition, it must be oxidized. The purpose of the oxidation treatment is to make the glass easy to join, but also to strengthen the wettability. The most common method is heating in a furnace or other methods to heat the metal surface to a high temperature, and at the same time, it can be filled with oxidizing gas.

At the same time, the heating temperature, holding time and the degree of oxidation must be controlled.

Then there is annealing and preheating of its connectors. In order to stabilize the structure of the connecting piece and reduce the stress of the joint, both the metal piece and the glass piece must be annealed before joining. For thick glass, the thicker the glass, the higher the heating temperature and the longer the holding time. In addition to preheating the metal before joining, the glass parts to be connected should also be properly preheated, otherwise the glass part may be broken during the cooling process.

(Huiputech)

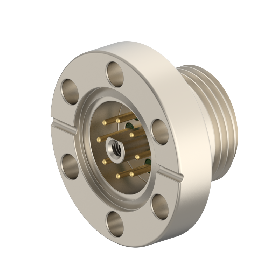

Z-S-CF16-0810S,Z-S-CF16-0810M,Z-S-CF16-0810L

2025-11-04

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.