PEEK is a kind of crystalline high temperature resistant thermoplastic engineering plastic with excellent comprehensive performance, and it is also a kind of polyaryletherketone polymer. Its long-term continuous working temperature is 240°C, can be used in 200°C steam, and has a flexible texture, excellent impact performance and elongation, corrosion resistance, radiation resistance, self-extinguishing, low smoke density during combustion, and excellent electrical properties. It has been applied in the aerospace industry, atomic energy industry, weaponry and high-end technology.

The main properties are:

(1) Heat resistance

Although the heat distortion temperature of unreinforced pure resin is only 160°C, the heat distortion temperature can reach 300°C or more after it is reinforced with glass fiber and carbon fiber. According to the long-term continuous use temperature evaluation method, the UL temperature index is determined to be 250°C.

(2) Mechanical properties

PEEK has good creep resistance at room temperature, and it is much higher than other heat-resistant resins with or without gaps.

(3) Variation of various physical properties with temperature

Although it drops around its glass transition temperature (143°C), it still maintains sufficient elastic modulus until its melting point (300°C). Its tensile strength varies with the enhancement situation, and maintains a certain strength until the high temperature area. The results of the aging test at 250°C show that not only the general resin cannot be compared with it, but it is even more stable than the recognized PPS with long-term heat resistance.

(4) Impact resistance

It is the toughest one among the heat-resistant resins.

(5) Flame retardancy

PEEK is self-extinguishing, without any flame retardant, it reaches 94V-0 (thickness 1.5mm) by UL standard. In addition, the amount of smoke generated during combustion is also very small.

(6) Chemical resistance

PEEK only dissolves in concentrated sulfuric acid and has good chemical resistance, especially in terms of acid and alkali resistance at high temperatures, which is much better than polyimide.

(7) Hydrolysis resistance

The water absorption rate of PEEK is very small, and the saturated water absorption rate at 23°C is only 0.5%. Moreover, it has good hot water resistance and can be used in pressurized hot water or steam at 300°C. It can be used continuously in hot water above 200°C. After immersing in hot water at 130°C for 11 days, the retention rate of the flexural modulus is above 90%, which is much higher than other resins.

(8) Wear resistance

It has good abrasion resistance equivalent to polyimide.

(9) Fatigue resistance

It has the best fatigue resistance among all resins.

(10) Radiation resistance

The ability to resist gamma radiation is very strong, surpassing polystyrene, which has the best radiation resistance among general-purpose resins. It can be made into a high-performance wire that can maintain good insulation capacity even when the gamma radiation dose reaches 1100Mrad.

(11) Peel resistance

PEEK has good peel resistance, so it can be made into thin-covered wires or magnet wires, and can be used under harsh conditions.

(12) Electrical performance

PEEK has good electrical insulation properties and can be maintained to a high temperature range. Its dielectric loss is also very small at high frequencies.

(Huiputech)

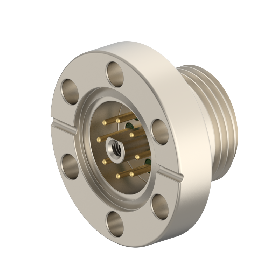

Z-S-CF16-0810S,Z-S-CF16-0810M,Z-S-CF16-0810L

2025-11-04

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.