Generally speaking, insulating ceramics are multiphase polycrystalline materials obtained by molding and sintering powder raw materials. The microstructure of ceramics can be mainly divided into three parts: matrix, grains and pores. Generally, pores and grains have good insulating properties. Substrates tend to exhibit greater electrical conductivity at high temperatures. Since the matrix part has a high impurity concentration and is a continuous phase in the structure, the insulation of the ceramic is easily affected by the matrix phase, and the conductivity of the matrix dominates the conductivity of the entire system.

The pores existing in the solid have little damage to the insulation performance, but when there are pores in the surface, the surface insulation will be significantly deteriorated because it is easy to absorb water and be polluted. Therefore, in principle, insulating ceramics should choose dense materials with few pores and no water absorption, and glaze their surfaces to prevent pollution and moisture absorption according to different usage conditions.

Generally, the insulation of a material is related to the purity of the material and the amount of impurities in the material. The higher the purity of the materials and the lower the impurity content, the better their insulating properties. This is because if impurities are introduced into insulating ceramics, it will produce impurity energy levels in the forbidden band like doped semiconductors, which will increase the charge carriers from the surface, decrease the resistivity, and reduce the dielectric strength as a result.

(huiputech)

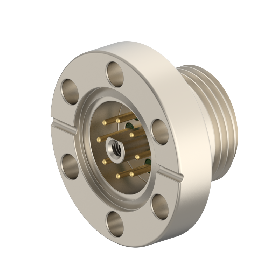

Z-S-CF16-0810S,Z-S-CF16-0810M,Z-S-CF16-0810L

2025-11-04

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.