advantage:

1. Lightweight

Plastics are generally lighter, with a density in the range of 0.83~2.3g/cm3, which is only 1/7~1/4 of steel and 1/2 of aluminum. This is very beneficial for reducing the weight of mechanical equipment, especially for vehicles, ships, airplanes, rockets, missiles, satellites and other cutting-edge technologies that require lightening of their own weight.

2. High specific strength-under normal circumstances, the strength of plastics is lower than that of metals, but the mechanical properties of various reinforced plastics can be compared with metals. Since its density is much smaller than that of metal, its specific strength (i.e. strength/density) is equivalent to or even higher than that of metal

3. Good chemical resistance-plastics have better chemical resistance than metals, and they have good corrosion resistance to chemicals such as acids and alkalis. It is of great significance to use plastics to make corrosion-resistant devices such as chemical equipment

4. Excellent electrical insulation-plastic is a poor conductor of electricity, with excellent electrical insulation, low dielectric constant and low dielectric loss. Provides excellent materials for the electrical industry and telecommunications, radar, aerospace and other technologies

5. Good anti-friction and wear resistance-most plastics have very small friction factors and can be used as anti-friction and wear-resistant materials. Some can even work effectively without lubricants and have good self-lubricating properties. Suitable as a friction material that works under harsh conditions such as the presence of abrasive particles or impurities

6. Excellent muffling and heat insulation-plastics have excellent muffling and heat insulation properties. The transmission friction parts made of plastic can reduce noise, reduce vibration and improve working conditions. Especially foam plastics are often used as sound insulation, heat insulation or heat preservation materials

Disadvantages:

1. General engineering plastics have low mechanical strength (especially poor rigidity), far less than metal materials

2. Low heat resistance, most of them can only be used at around 100℃, only a few varieties can be used at around 200℃

3. Extremely poor thermal conductivity, large thermal expansion coefficient, easy to age, easy to burn, and the creep value (the so-called cold fluidity) at room temperature is also relatively large

(Huiputech)

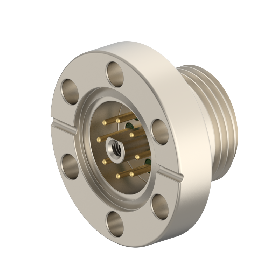

Z-S-CF16-0810S,Z-S-CF16-0810M,Z-S-CF16-0810L

2025-11-04

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.