Cracks, lack of fusion and lack of penetration in welded joints are more harmful than pores and slag inclusions. They not only reduce the effective load-bearing cross-sectional area of the structure, but also cause stress concentration and may induce brittle fracture. Especially for cracks, there is a notch effect at the tip, which easily induces a three-way stress state, which leads to the instability and propagation of the cracks, resulting in the fracture of the entire structure, so cracks (especially delayed cracks) are the most dangerous in the welded structure. defect.

Cracks in welded joints are often flat. If the loading direction is perpendicular to the plane of the crack, the two ends of the crack will cause severe stress concentration. The pores in the weld are generally in the shape of a single ball or worm, so the stress concentration around the pores is not serious. The single inclusion in the weld has a different shape, and the stress concentration around it is not serious. However, if there are dense pores or inclusions in the weld, under load, if the pores or inclusions are connected, it will cause the expansion of the stress zone and the sharp rise of the stress value.

Poor shape of the weld, excessive convexity of the fillet weld, misaligned edges, corner distortion and other external defects of the welded joint will also cause stress concentration or additional stress.

Geometric discontinuities such as weld height increase, misalignment and angular deformation, some of which are allowed by the current specifications, will cause stress concentration in the welded joint area. Due to the difference of joint forms, stress concentration will also occur. Among the commonly used joint forms of welded structure, the stress concentration of butt joints is the smallest, and the stress concentration of angle joints, T-shaped joints and front lap joints are similar. T-shaped joints in important structures, such as H-shaped plate beams that work under dynamic load, can be grooved to reduce the stress concentration at the joints; but lap joints cannot do this, and the side lap welds are The stress distribution on the entire length of the weld is very uneven, and the longer the weld, the more serious the unevenness. Therefore, the general steel structure design code stipulates that the calculated length of the side lap weld shall not be greater than 60 times the size of the weld leg. After exceeding this limit value, even if the length of the side lap weld is increased, the stress peak at both ends of the weld will not be reduced.

Compared with the structure with cracks and pores occupying the same area, the fatigue strength of the former is 15% lower than that of the latter. For incomplete penetration, as the area increases, the fatigue strength decreases significantly. Moreover, the influence of such flat defects on fatigue strength is related to the load direction.

(Huiputech)

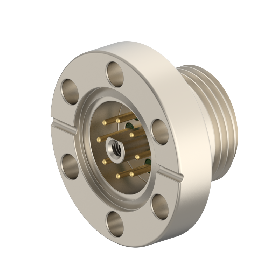

Z-S-CF16-0810S,Z-S-CF16-0810M,Z-S-CF16-0810L

2025-11-04

Contact : Martin

Tel : +86 18588203671

Mobile : +86 18588203671

Fax : +86 18588203671

Email : Martin@huiputech.com

Address : 3/F, Building F, GLORY Technology Park, No.2 Baolong 5th Road, Longgang District, Shenzhen, Guangdong, China.